Overmoulding

Medical Moulded Products are experts in the overmoulding of plastic, metal and most other non plastic materials in a class 7 or class 5 cleanroom environment.

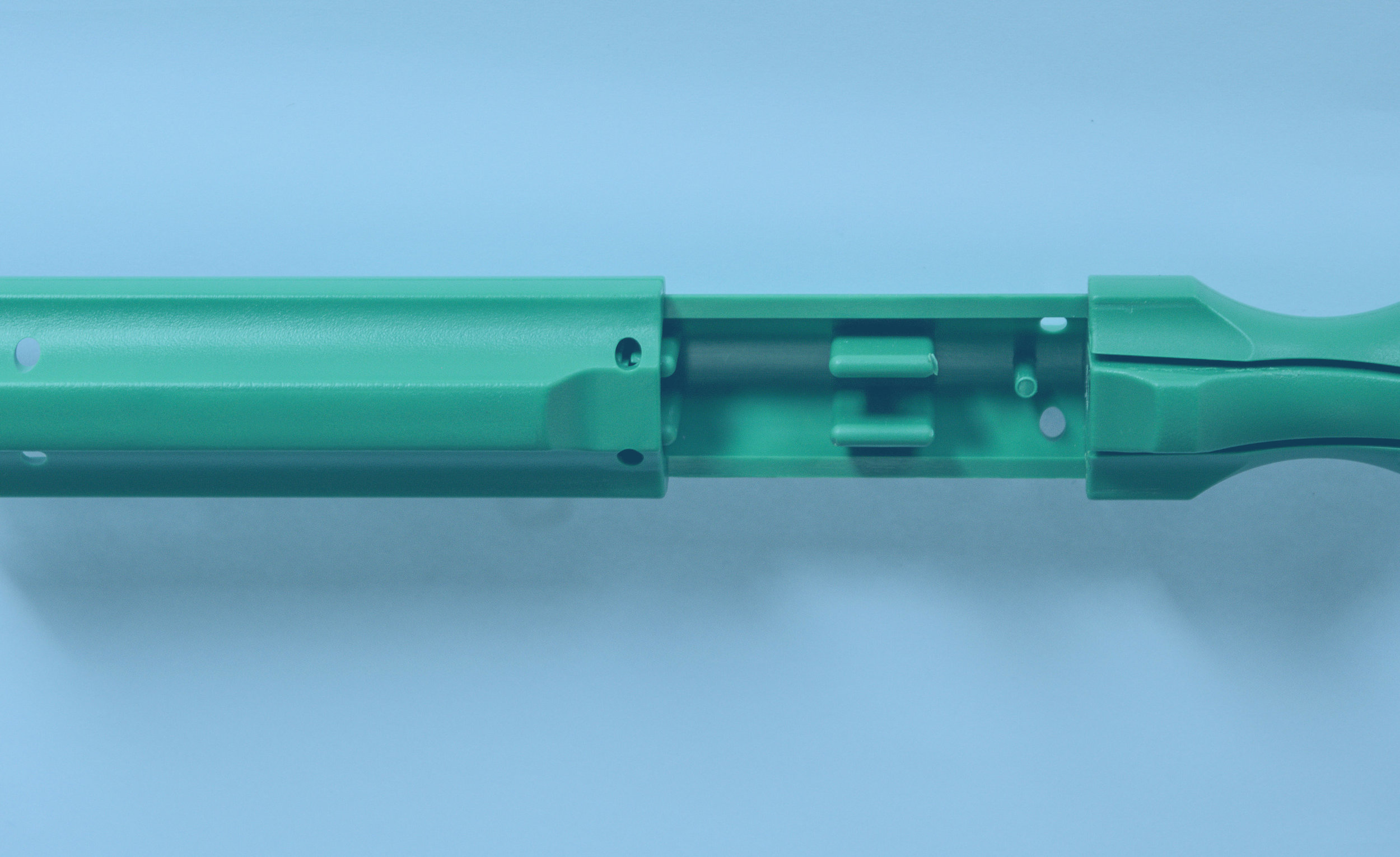

Overmoulding

MMP are experts in the overmoulding of plastic, metal and most other non plastic materials in a class 7 or class 5 cleanroom environment. Overmoulding is carried out by loading the part to be overmoulded into an injection moulding tool into a pre determined position.

The moulding process is then started and the plastic material is injected into the tool and around the overmoulded part. Tooling has to be accurate enough to hold the part in place without damaging it during the injection moulding process and often the part to be overmoulded has some form of retention added to it for strength of bond.

MMP can help you with your bespoke design to ensure your overmoulded product meets your needs and those of the injection moulding process. MMP can procure tooling on your behalf, in which case we take full responsibility for tool design and manufacture through to your part approval, or alternatively we are happy to produce your overmoulded part from tooling you supply to us.

MMP also have equipment to torque test overmoulded product should that be a requirement to validate strength of bond. Please contact us to discuss your requirements for overmoulding. MMP are committed to customer service and quality and are a supplier you can trust.